How to do it for a non-sash window. Often the blinds are fitted in the recess of a window reveal. Because the headrail is 44mm deep it is usually fitted in front of the existing frame, fixed either up into the soffit or into the window frame (see below).

Measurements needed for non-sash windows

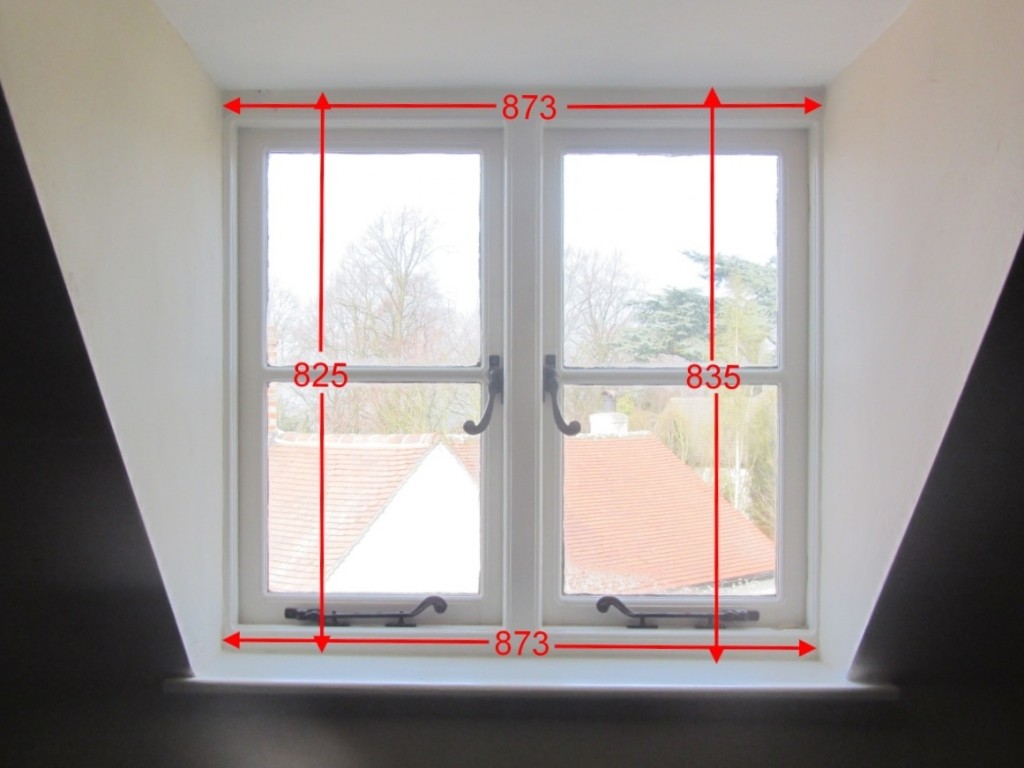

We will need the exact measurements of the width & height of your recess, together with photos showing each corner of the window (without curtains or blinds), plus the floor to sill height. Download instructions (pdf) here, or a Word version here. The blind will be made about 8mm narrower than the recess so it doesn’t rub on the walls.